THE SOLUTION

Variable Compression Ratio

The compression ratio indicates how much the air-fuel mixture is compressed before ignition. A higher CR ratio improves efficiency and power but increases the risk of knock. A lower ratio is safer regarding knock and peak combustion pressure but less efficient.

Most engines use a fixed compression ratio, forcing a compromise between performance and efficiency. With VCR, that compromise is no longer necessary. The engine can continuously adjust to operate at its optimal compression ratio in every condition.

How it works

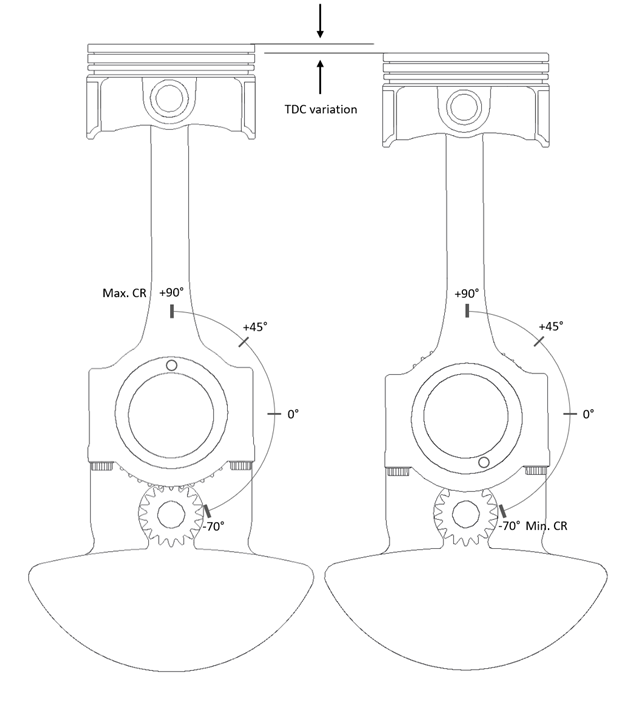

The VCR system uses an eccentric to adjust the engine’s compression ratio dynamically. The eccentric’s position determines the compression: at 90 degrees, the compression ratio is at it’s highest; at -70 degrees, it’s at its lowest. The range between these points depends on the eccentricity.

A key innovation of the system is that the eccentric rotates at half the speed of the crankshaft and in the same direction. This slower rotation reduces friction by deviding the speed over two bearings instead of one, reducing friction.

The system can switch between its highest and lowest compression ratio in just 0.2 seconds, thanks to a fast hydraulic actuator. This makes the Gomecsys VCR system exceptionally responsive and capable of optimizing performance and fuel efficiency under varying engine loads and conditions.

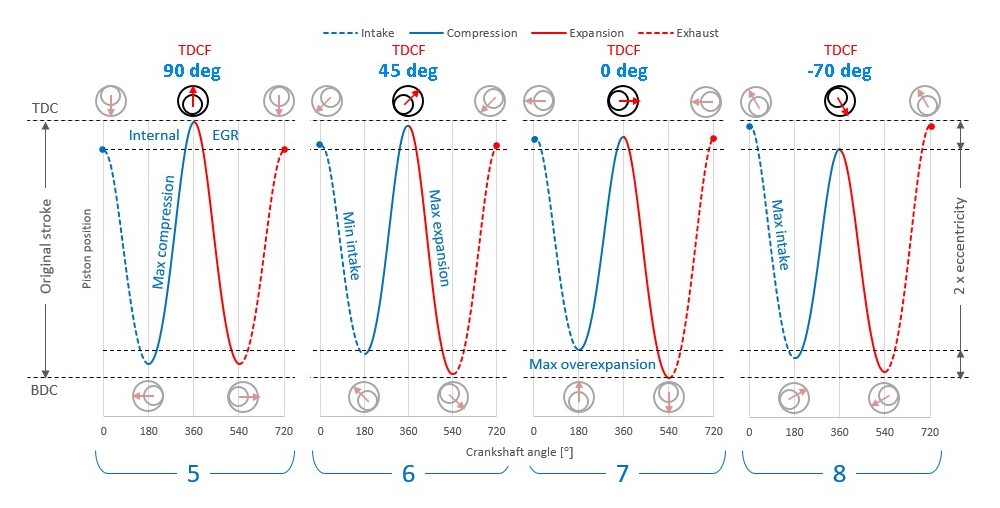

Different TDC’s within one cycle

At max compression ratio the eccentric is in its highest position when in TDC firing, but one crankshaft revolution further the eccentric will thus be in its lowest position in TDC gas exchange. See cycle (5). This gives 2 advantages: 1 = internal EGR, 2 = it gives more freedom for the valves to move in TDC gas exchange.

Reduced intake stroke

In part load the intake stroke is reduced and the expansion stroke increased. When the eccentric is in its 45 degrees position (6) in TDC firing, the intake stroke is at its minimum and the expansion stroke at its maximum.

Overexpansion

The eccentrics running at half the crankshaft speed means that the eccentric rotates only 180 degrees per crankshaft revolution. When the eccentric is at its mid-range position (0 degrees) in TDC firing it will be at its lowest possible BDC position at the end of the expansion stroke and at its highest BDC position at the beginning of the compression stroke (7) and thus creating true overexpansion.

Maximum intake stroke in full load

When the eccentric is at its lowest position in TDC firing the intake volume is at its maximum (8).

ADVANTAGES

Key benefits of our VCR system

Our Variable Compresson Ratio (VCR) technology offers unique advantages across various industries, enabling manufacturers to use a single engine configuration that dynamically adapts to different requirements.

Traditionally, manufacturers have developed multiple engine variants with fixed compression ratios to meet specific operational needs. VCR technology eliminates this complexity, allowing one engine to deliver optimal performance across diverse applications and fuels. This reduces costs, increases efficiency, and simplifies production processes.

CO2 reduction

By adjusting the compression ratio to suit real-time driving conditions, the system can reduce CO₂ emissions by up to 10% in the WLTP cycle. The use of hydrogen enables climate-neutral combustion with zero CO₂ emissions and near-zero NOx.

Enhanced performance

The system can also deliver up to 5% improvement in engine performance by optimizing combustion efficiency across the operating range.

No additional Friction

The Gomecsys eccentric rotates in the same direction as the crankshaft and the load is divided by two bearings, ensuring no additional friction is introduced to the system.

Hydraulic actuation

A hydraulic actuator enables the system to switch from maximum to minimum compression ratio in just 0.2 seconds.

No limit in Max Combustion Pressure

In the minimum compression ratio (CR) position the eccentric aligns with the combustion forces transmitted through the conrod. This means that the load on the VCR gears when in full load operation, and in the minimum CR position, is actually the lowest load for the VCR gears. Our in-house developed hydraulic actuator features an integrated pressure relief valve that opens at a pressure that represents the durability load limit for the VCR gears and automatically adjusts to a lower CR position, protecting the VCR gears and ensuring long-term durability.

Minimal additional production costs

The system is mechanically simple, requiring few additional components and keeping production costs low.

No impact on existing engine architecture

The system integrates with the existing engine layout without introducing any changes to the core structure.

Seamless integration

VCR supports the transition to alternative fuels, such as biofuels, synthetic fuels, and hydrogen.

Various applications

Join Us on the Journey to Net Zero

At Gomecsys, we don’t just build technology; we build the future. By collaborating with industry leaders and continuously innovating, we are driving progress toward a cleaner, more sustainable tomorrow.

Are you ready to join us on this journey? Let’s work together to shape a world where advanced engine technologies enable sustainable mobility for all. Whether you’re an OEM, an industry partner, or a forward-thinking innovator, Gomecsys is here to help you achieve your goals.

Contact us today to learn more about our solutions or explore opportunities for collaboration. Together, we can drive the future of engine technology-efficient, adaptable, and sustainable.