THE GOMECSYS VCR SYSTEM

Using an extreme VCR range from 10:1 to 24:1 to get the best efficiency out of both H2 and gasoline

Initial Concept and Design

Our VCR-H concept is using a VCR range from 10:1 al the way up to 24:1, using a 3 mm eccentricity. Up to 6 bar BMEP the engine is operating on directly injected hydrogen, using a CR between 24:1 and 18:1. To optimize the efficiency of the engine in part load operation, we are using (diesel like) diffusion and lean combustion (Lambda >2).

At engine loads above 6 bar BMEP the engine is operating on gasoline, using a CR between 13:1 and 10:1 at Lamba one and normal gasoline SI combustion.

This concept offers a major step in CO2 reduction with a limited amount of H2 on board of the vehicle.

For normal gasoline engines, a CR range of 9:1 to 16:1 delivers measurable benefits, including a 10% reduction in CO₂ emissions during part-load operation. This translates to substantial environmental gains and significant cost savings for manufacturers and consumers alike.

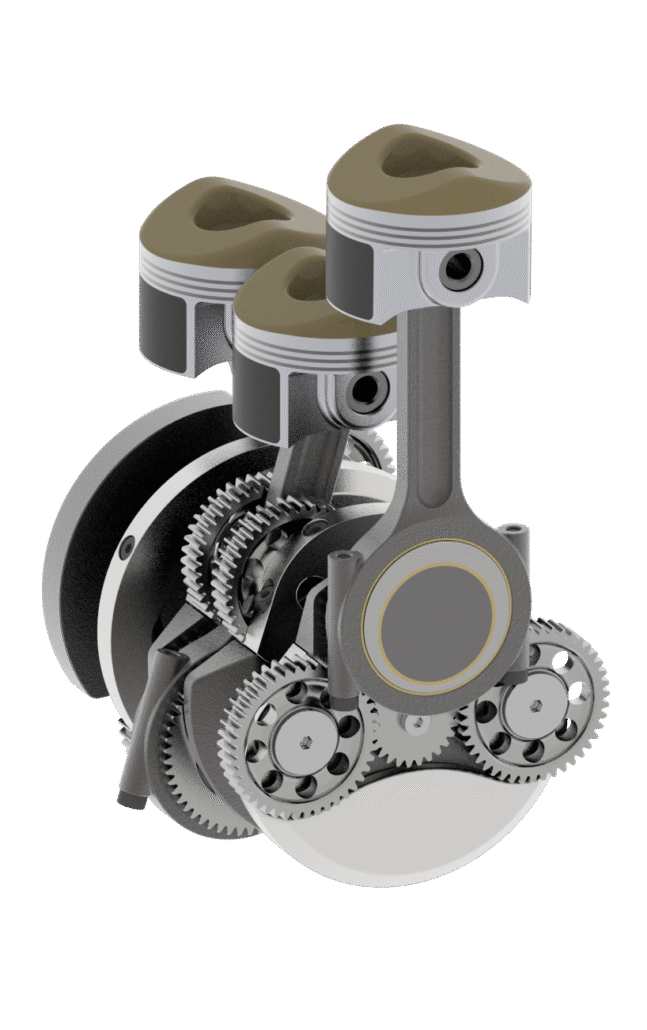

No limitations for the maximum combustion pressure

Turbocharged engines are becoming increasingly popular due to their ability to deliver higher power outputs from smaller, more efficient engine designs. The enhanced gear mechanism of the Gomecsys VCR system is specifically engineered to meet the demanding requirements of 3- and 4-cylinder turbocharged engines. In the minimum CR position there is actually no limitation for the combustion pressure. Actually the load on the VCR gears is at a minimum when the engine is operating at full load, while at the minimum CR position. This remarkable fact is realized because with the eccentric at the minimum CR position the combustion forces (transmitted on the eccentric by the conrod) are inline with the eccentricity. Ensuring that the engine can handle the elevated pressures and thermal loads associated with turbocharging, all while maintaining durability and reliability. This makes it possible for manufacturers to deliver exceptional performance and fuel economy in smaller, more efficient engine configurations.

Improved Durability without additional friction

Modern engines are optimized regarding friction. Although the VCR crankshaft is using additional bearings and gears, there is no additional friction.

This amazing result is acheived because the eccentric is always rotating around the crankpin at half the speed of the crankshaft, and the conrod big-end is also rotating on the eccentric with half the speed of the crankshaft. Two bearings running at 3000 rpm produce less friction than one bearing running at 6000 rpm.

The Gomecsys VCR system is realizing 10% CO2 reduction in part load operation because there is no additional friction that has to be overcome before gaining efficiency from increased CR.

Fuel Efficiency and CO₂ Reduction

Fuel efficiency and emissions reduction are at the core of the Gomecsys VCR system’s design. By adjusting the compression ratio to suit specific driving conditions, the system ensures that engines operate at peak efficiency under all circumstances. During part-load operation, the system’s ability to increase the compression ratio results in an 10% reduction in CO₂ emissions, a significant achievement in meeting stringent global environmental regulations. For consumers, this translates to lower fuel costs and a reduced carbon footprint, making vehicles equipped with VCR technology both economical and environmentally friendly.

Seamless Integration for OEMs

One of the most practical advantages of the Gomecsys VCR system is its seamless integration into existing passenger car engine architectures. Designed with manufacturers in mind, the drop in system requires minimal modifications to current engine designs, reducing development time and associated costs. This makes it an attractive solution for automakers looking to enhance performance and efficiency without the need for costly reengineering efforts. With its straightforward integration process, the VCR system delivers immediate benefits, allowing OEMs to stay ahead in a competitive market.

Redefining the Future of Engine Design

The automotive industry is undergoing a transformative shift, driven by the need for cleaner, more efficient technologies. The Gomecsys VCR system is supporting this change by providing a versatile, future-ready solution that enhances engine performance while reducing environmental impact. Its ability to adapt dynamically to diverse fuel technologies, including hydrogen and ethanol blends, positions it as a critical enabler of sustainable mobility. With the strengthened VCR system, Gomecsys empowers automakers to innovate without compromise, offering a solution that meets the demands of today while anticipating the challenges of tomorrow. From optimizing turbocharged engines to enabling greener hybrid solutions, the Gomecsys VCR system is reshaping the possibilities of passenger car engine design.

Let’s Drive the Future Together

Gomecsys is dedicated to helping automakers revolutionize passenger car engines with advanced VCR technology.

Whether you’re exploring ways to enhance engine performance, reduce emissions, or adapt to new fuel technologies, our team is here to collaborate. Contact us today to schedule a detailed technical presentation and discover how Gomecsys VCR technology can meet your needs and drive innovation in your next-generation engines. With Gomecsys, the future of engine design is here-efficient, sustainable, and ready for the road ahead.