DESIGN AND TECHNICAL

Performance and supporting sustainability

while minimizing impact on your current design

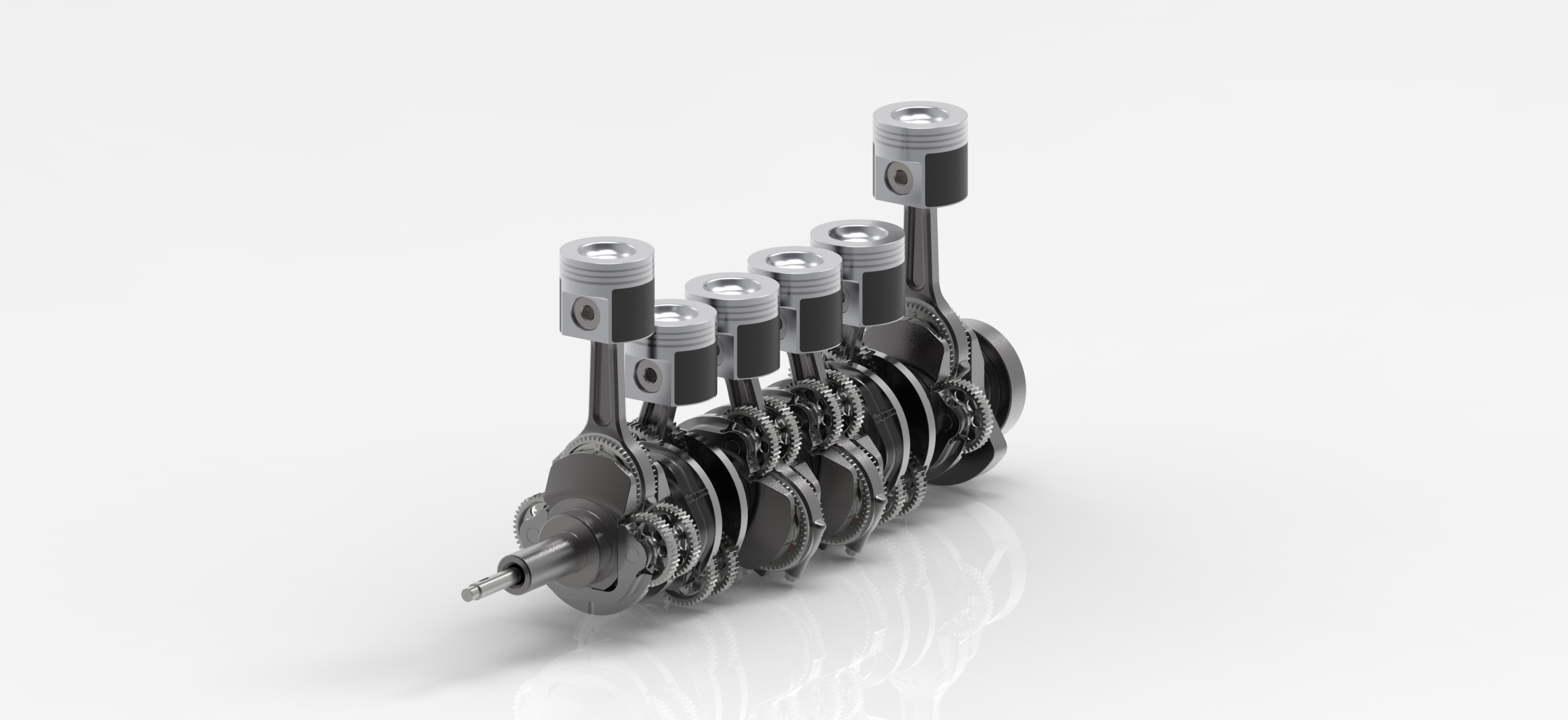

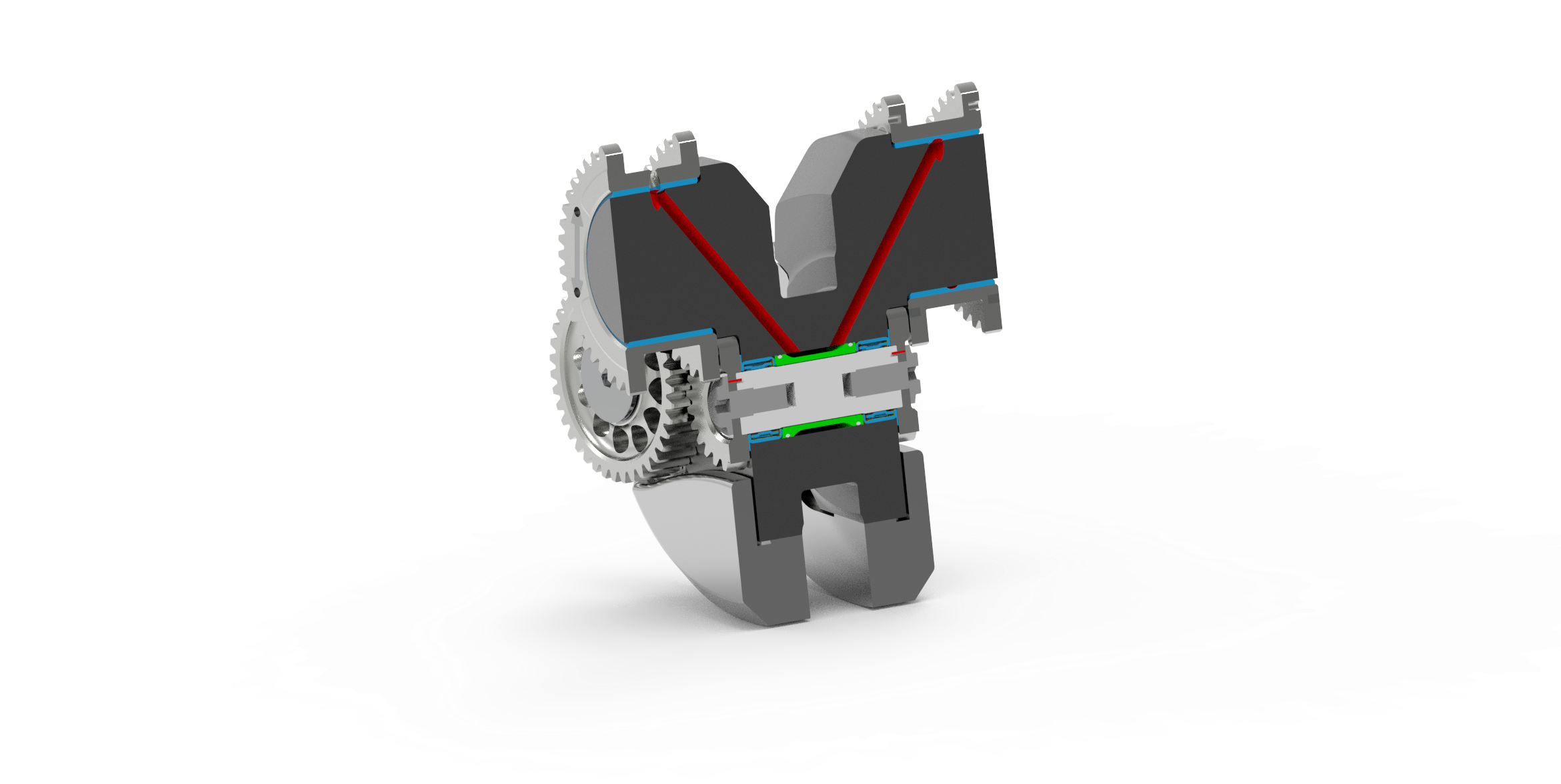

Our Variable Compression Ratio technology is designed to integrate seamlessly into your engine designs, enhancing performance and supporting sustainability while minimizing impact on your current product design. Here’s how our process works:

Initial Concept and Design

We provide free concept designs tailored to your engine architecture, demonstrating how VCR technology improves efficiency and performance. These designs form the basis of detailed technical presentations, offering a clear vision of the system’s performance and benefits. This process allows OEM’s to see exactly how the Gomecsys VCR system enhances their engine technology.

Engineering Expertise and In-House Capabilities

Our patented VCR systems undergo rigorous design and Finite Element Analysis (FEA) to ensure strength and reliability. Using advanced software we optimize hydrodynamic bearings, gears, and crankshafts to deliver precision and durability. We also leverage high-end gear development software from TBK (Germany) and advanced gear simulation capabilities through Mahle Transmission ZG GmbH for precise and reliable gear systems. Additionally, our engineering team specializes in assembling VCR crankshafts and meticulously measuring all clearances to ensure optimal performance. Every prototype VCR crankshaft delivery includes a detailed assembly report, ensuring transparency and quality assurance.

R&D TESTING SERVICES

Our R&D engine enables rapid design, construction, and testing of new projects

Our expertise in developing and testing prototypes spans both in-house capabilities and collaborations with world-class facilities.

For OEM engines, our in-house developed R&D engine enables rapid design, construction, and testing of new projects. Offering detailed performance evaluations such as combustion efficiency analysis, precise VCR (Variable Compression Ratio) shaft torque measurements, and base calibration of prototype engines to establish optimal performance benchmarks. Furthermore, our VCR actuation system is fine-tuned for smooth and reliable operation, ensuring peak engine performance.

Motorbike Engine Testing

Our tailored in-house testing capabilities for motorbike engines include a combustion analyzer for detailed performance evaluations, precise VCR shaft torque measurements and a dedicated VCR-ECU for optimal engine control and adaptability. We perform base calibrations of prototype VCR engines to establish optimal benchmarks and test and optimize the VCR actuation system for smooth, reliable operation. Real-world performance validation is achieved through rolling road dyno testing for motorbikes.

Truck and Car Engine Testing

For truck and car engines, we collaborate with globally renowned testing facilities to validate performance under rigorous conditions. Partnerships with institutions like TNO (Netherlands) for truck engine testing and Ricardo (UK) for both truck and car engines ensure that our prototypes meet the highest industry standards. These advanced testing capabilities guarantee exceptional results in real-world scenarios, confirming the reliability and efficiency of our innovative designs.

DUAL-FUEL AND HYDROGEN SOLUTIONS

Operate on hydrogen in part-load conditions, reducing emissions significantly

Our expertise extends to dual-fuel and hydrogen-based combustion systems. We design solutions that allow engines to:

Operate on hydrogen in part-load conditions, reducing emissions significantly. Research shows that adapting diesel engines to run on hydrogen during part load operation can achieve up to an 80% reduction in CO₂ emissions and near zero NOx emissions.

Switch seamlessly to diesel at full load for maximum flexibility and performance. These dual-fuel systems combine the environmental benefits of hydrogen in low-load operations with the power and efficiency of diesel when needed.

By integrating these technologies, we aim to achieve near-zero NOx emissions and a significant reduction in CO₂ output, contributing to more sustainable and environmentally friendly engine solutions.

COLLABORATIVE INTEGRATION

Performance and supporting sustainability while minimizing impact on your current design

At Gomecsys, we pride ourselves on being a reliable partner for OEMs worldwide, providing cutting-edge solutions tailored to their specific needs. Our collaboration process starts with a detailed understanding of the OEM’s requirements, followed by:

Custom Design and Conceptualization

We work hand-in-hand with OEM engineering teams to create custom designs that integrate seamlessly into existing platforms or new engine architectures.

Prototyping and Validation

Leveraging our in-house R&D capabilities, we develop prototypes optimized for performance and reliability.

Training and Knowledge Sharing

We ensure OEM teams are equipped with the technical know-how to maximize the benefits of our Variable Compression Ratio systems, offering workshops and technical documentation.

Continuous Improvement and Support

Our commitment doesn’t end with implementation. We provide ongoing support and continuously refine our solutions based on feedback and performance metrics, ensuring long-term success.

Partnering with Gomecsys

OEMs gain access to innovative technology, expert guidance, and unparalleled support, enabling them to stay ahead in an ever-evolving automotive landscape.

Join Us on the Journey to Net Zero

At Gomecsys, we don’t just build technology; we build the future. By collaborating with industry leaders and continuously innovating, we are driving progress toward a cleaner, more sustainable tomorrow.

Are you ready to join us on this journey? Let’s work together to shape a world where advanced engine technologies enable sustainable mobility for all. Whether you’re an OEM, an industry partner, or a forward-thinking innovator, Gomecsys is here to help you achieve your goals.

Contact us today to learn more about our solutions or explore opportunities for collaboration. Together, we can drive the future of engine technology-efficient, adaptable, and sustainable.